Where are you on your Smart Factory journey?

Digital manufacturing strategy is on the agenda of every CIO/CEO. But, how do you know where to start? Phrases such as Digital Twins, Connected Supply Chain and Artificial Intelligence (AI) are common buzzwords in manufacturing media. How is your 2022 digital transformation plan shaping up? Whilst augmented reality, and digital twins’ solutions, might seem to be the answer, they’re not the place to start. Leading manufacturers are changing the face of Production, Operations and Consumer relationships through agile manufacturing, but the strategy must be business-led (don’t start with the technology!).

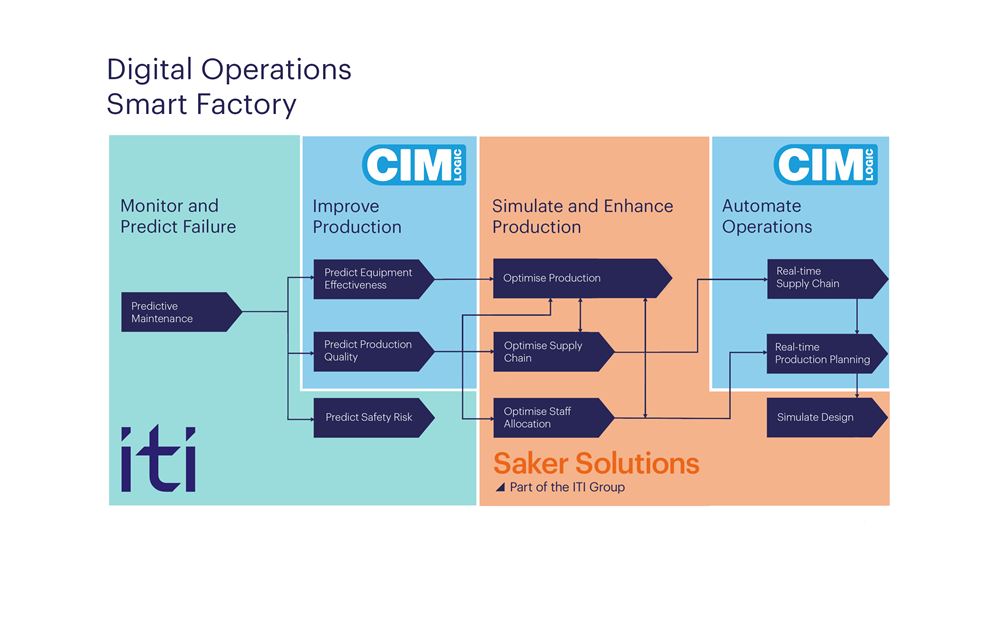

Cimlogic work with companies on their digital transformation journey, reviewing current technology and developing a reference architecture for forward planning. Successful digital transformation needs visibility (and understanding) of the complete design cycle and supply chain cycle, facilitated through a connected supply chain and an integrated digital enterprise.

From ‘Good’ to ‘Smart’ – your Digital Transformation journey …

1. Create a Great Factory

To achieve a Smart Factory, you first need a ‘really good’ Factory. Understand your business KPIs and challenges, analyse these and identify appropriate solutions, designed to maximise ROI and business benefit. Solutions such as basic MES/OEE and Smart Andon can form part of step 1 on the Smart Factory journey, addressing challenges around productivity/performance, quality and compliance, and cost of goods.

2. Advanced MES and Vertical Integration

Once the smart factory foundations are in place, you can start planning the strategy to address additional challenges, including sustainability, and on-time delivery in full (OTIF). Beyond traditional OEE projects, MES solutions include quality, maintenance, inventory, and energy. The availability of consistent, high-quality data, in turn, enables data analytics and the implementation of machine learning solutions delivering innovative process improvements and real business value.

Vertical integration forms the backbone of digital manufacturing and the connected supply chain. Vertical integration between SCADA, MES, ERP and business systems allows companies to realise additional business benefits, combining application capabilities and enabling an agile manufacturing facility.

3. Manufacturing Digital Core and the Integrated Enterprise

Many manufacturers have developed internal systems in a somewhat isolated manner; whilst companies are making huge investment in technology (PLM, CRM, ERP, SCADA and MES etc), these often operate in silos, with current point to point integration preventing companies realising the full benefit of combining application capabilities. Integration of PLM and CRM systems with the traditional ‘manufacturing’ applications is integral to the manufacturing digital core, without which companies are ill-equipped to realise the benefits of a truly Integrated Enterprise.

Prioritise the manufacturing digital core as a fundamental step on your Smart Factory journey. Get the digital core right first, then layer the smart technology on top of it, otherwise you’re just implementing tech on tech (and potentially wasting investment).

4. Connected Supply Chain

10-15 years ago the Integrated Enterprise was the holy grail for manufacturers. The new guiding light is the Connected Supply Chain. Customers have a relationship with a product and manufacturers want to develop that relationship, respond to feedback, and initiate proactive innovations with regards to new products, service, and delivery. Shareholders’ expectations increase alongside developments in technology. Companies are expected to respond rapidly to unexpected issues with suppliers, external factors, and customer demand. Increased connectivity and visibility across the supply chain allows timely responses to unforeseen events as well as reduced risk, fast product turnaround and customisation according to demand.

The PRODUCT – MAKE – CONSUMER relationship is key. Closed-loop manufacturing is happening today and is driven by digital technology, with strategy ownership at CIO/CXO level.

Leading companies today are using their supply chain to gain a competitive edge. The final stage of the Digital manufacturing/Smart Factory journey is the digital transformation of supply chains, allowing companies to differentiate in key areas:

- Improved speed to market and product innovation. Direct access to customers to increase sales and reorders/customisations, leading to competitive differentiation and increased revenue. Leading companies can react to ever-increasing customer choice and demand.

- Reduced costs of raw materials and quality compliance. Increased visibility and connectivity, through automation and real-time data analysis, leads to reduced cost to serve and delivery charges. Raw materials are a key piece of the supply chain; supplier flexibility (connectivity and visibility) is crucial.

- Improved efficiency of assets. Automated inventory management and improved connectivity reduce downtime and improve production efficiency. Manufacturers need an agile factory.

Are you ready to connect? Embrace Digital Manufacturing with Cimlogic

Cimlogic’s customer-centric RAISE™ methodology centres around understanding your business KPIs and challenges, analysing these and delivering appropriate solutions, designed to maximise ROI and business benefit. RAISE™ utilises industry best practices from BCS business analysis processes and LEAN Methods, taking a business-focused approach to manufacturing projects, understanding the key elements of People, Processes and Technology to solve business challenges and meet stated goals.

Remember, Digital Manufacturing is not just an engineering project. Whatever the starting point on the Smart Factory journey, Cimlogic works in partnership with leading manufacturers, from achieving a ‘really good factory’ to a fully integrated, connected supply chain.

Cimlogic support clients in seamlessly joining supply chain and operational practices together with digital technologies. Are you ready to answer the questions of tomorrow, today? Remember, digital is firmly on the manufacturing agenda for 2022. If it’s not on yours, why not?

Want to read more about the manufacturing digital core? Interested in how the connected supply chain supports the relationship between product, operations and the customer? Download the full article below.

Oops! We could not locate your form.